Bottom price Thermoforming Vacuum Packaging Machine - High-speed impact IQF tunnel freezer – INCHOI

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Thawing Machine, Sampack Vacuum Packing Machine Price, Horizontal Sterilizer, All the time, we have been paying attention on all details to insure each product satisfied by our customers.

Our rewards are lower costs,dynamic profits team,specialised QC,potent factories,high-quality services for Thawing Machine, Sampack Vacuum Packing Machine Price, Horizontal Sterilizer, All the time, we have been paying attention on all details to insure each product satisfied by our customers. Bottom price Thermoforming Vacuum Packaging Machine - High-speed impact IQF tunnel freezer – INCHOI Detail:

FLUIZED QUICK FREEZER

Product Description:

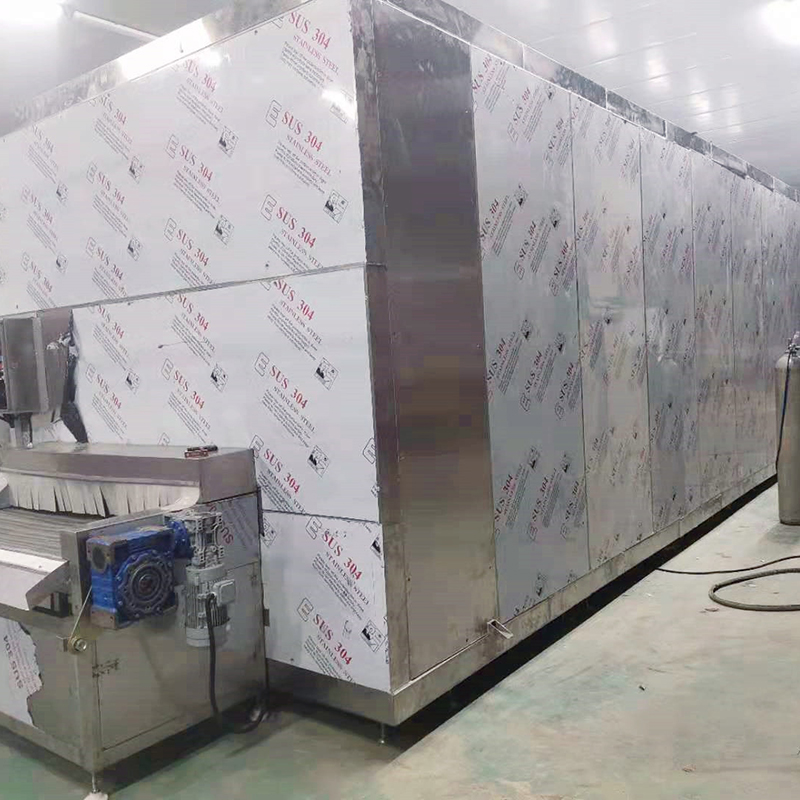

The INCHOI High-speed impact IQF tunnel freezer adopts an advanced design independently developed, which is efficient in freezing during operation and energy-saving in operation.

INCHOI high-speed impact technology breaks the traditional concept of rapid cooling only by increasing the wind speed, and greatly shortens the freezing time.

Suitable for individual quick freezing of thin, flat products and small-volume bulk products. The material enters from the entrance, and the upper and lower sides collide and expand through high-speed cold air at the same time, absorb heat, and quickly cool down, so as to ensure two-way freezing of food and achieve the purpose of rapid freezing.

Structural features

1. INCHOI’s high-speed impact freezer meets the requirements of HACCP, and the equipment materials meet the food safety regulations.

2. The “two-way cold air impact technology” breaks the traditional technical constraints of increasing wind speed and cooling, and the freezing time is greatly shortened. The efficiency of freezing fish fillets is more than double that of the traditional individual freezer; the time for freezing shrimp is more than two to three times shorter than that of the traditional individual freezer.

3. The loss of cooling capacity is small, the quick-freezing effect is improved, and the energy is saved.

4. The design of the quick-freezer is reasonable, easy to clean, and has no dead ends.

5. The mesh surface of the mesh belt is flat, which can ensure the shape and appearance quality of the product.

6. The mesh belt adopts frequency conversion reducer, which can adjust the freezing time and traveling speed according to the requirements of different foods.

7. The product can be frozen directly on the mesh belt, or it can be frozen on the plate, it can be single frozen, bag frozen or tray frozen.

|

Model |

Capacity/hour |

Freezing time (min) |

Feed temperature |

Discharge temperature |

Temperature inside |

| YCDZ-300 | 300KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-500 | 500KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-1000 | 1000KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-2000 | 2000KG | 20-40 | ≤40 | -18℃ | -35℃ |

Product detail pictures:

Related Product Guide:

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for Bottom price Thermoforming Vacuum Packaging Machine - High-speed impact IQF tunnel freezer – INCHOI , The product will supply to all over the world, such as: Doha, Uruguay, Colombia, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!