China Factory for Vacuum Fried Chips Machine - High-speed impact IQF tunnel freezer – INCHOI

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Batch Retort, Autoclave Sterilization Machine, Vacuum Chamber Machine, Welcome friends from all over the world come to visit, guide and negotiate.

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Batch Retort, Autoclave Sterilization Machine, Vacuum Chamber Machine, Welcome friends from all over the world come to visit, guide and negotiate. China Factory for Vacuum Fried Chips Machine - High-speed impact IQF tunnel freezer – INCHOI Detail:

FLUIZED QUICK FREEZER

Product Description:

The INCHOI High-speed impact IQF tunnel freezer adopts an advanced design independently developed, which is efficient in freezing during operation and energy-saving in operation.

INCHOI high-speed impact technology breaks the traditional concept of rapid cooling only by increasing the wind speed, and greatly shortens the freezing time.

Suitable for individual quick freezing of thin, flat products and small-volume bulk products. The material enters from the entrance, and the upper and lower sides collide and expand through high-speed cold air at the same time, absorb heat, and quickly cool down, so as to ensure two-way freezing of food and achieve the purpose of rapid freezing.

Structural features

1. INCHOI’s high-speed impact freezer meets the requirements of HACCP, and the equipment materials meet the food safety regulations.

2. The “two-way cold air impact technology” breaks the traditional technical constraints of increasing wind speed and cooling, and the freezing time is greatly shortened. The efficiency of freezing fish fillets is more than double that of the traditional individual freezer; the time for freezing shrimp is more than two to three times shorter than that of the traditional individual freezer.

3. The loss of cooling capacity is small, the quick-freezing effect is improved, and the energy is saved.

4. The design of the quick-freezer is reasonable, easy to clean, and has no dead ends.

5. The mesh surface of the mesh belt is flat, which can ensure the shape and appearance quality of the product.

6. The mesh belt adopts frequency conversion reducer, which can adjust the freezing time and traveling speed according to the requirements of different foods.

7. The product can be frozen directly on the mesh belt, or it can be frozen on the plate, it can be single frozen, bag frozen or tray frozen.

|

Model |

Capacity/hour |

Freezing time (min) |

Feed temperature |

Discharge temperature |

Temperature inside |

| YCDZ-300 | 300KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-500 | 500KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-1000 | 1000KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-2000 | 2000KG | 20-40 | ≤40 | -18℃ | -35℃ |

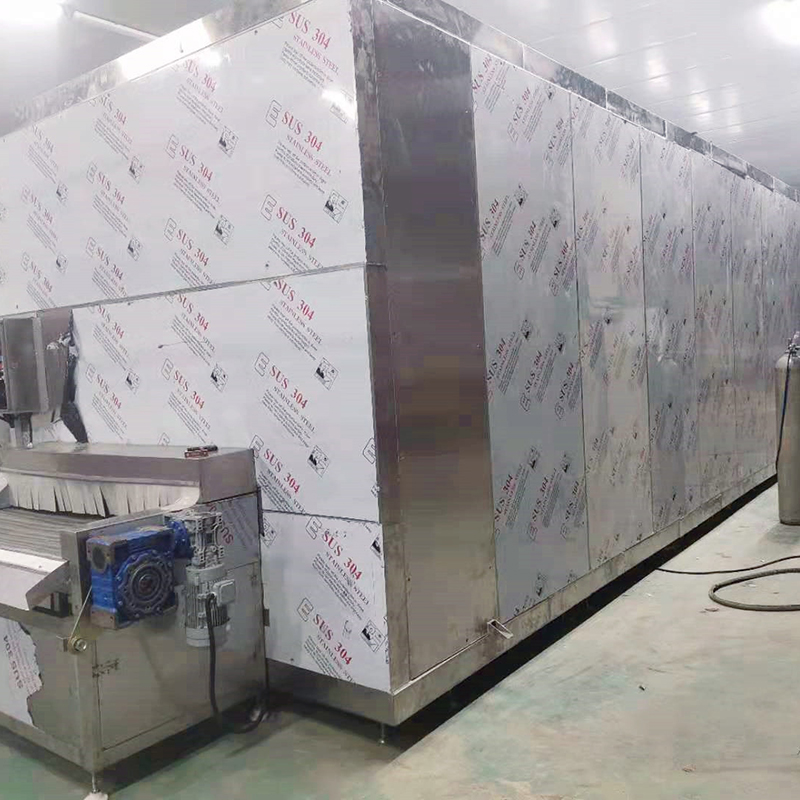

Product detail pictures:

Related Product Guide:

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for China Factory for Vacuum Fried Chips Machine - High-speed impact IQF tunnel freezer – INCHOI , The product will supply to all over the world, such as: Qatar, Swedish, India, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.