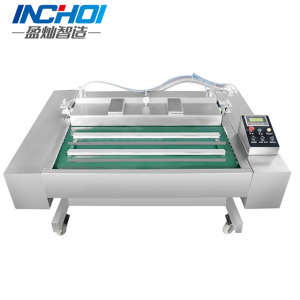

DZ600/2S tilt adjustable Vacuum packaging machine

Technical Parameters:

| Vacuum chamber size (mm) | 600×650×120 |

| Sealing size | 600×(8-10) ×4 bars |

| Packaging capacity (times/hour) | 90-360 |

| Weight (kg) | 230 |

| power supply | 380V 50HZ 2KW |

| Dimensions (mm) | 1220×680×900 |

The tilt angle of the machine can be adjusted from 0 to 90 degrees. The main function is to ensure that the vacuum packaging or packaging abrasives can be placed vertically and the materials will not overflow. The tilting vacuum packaging machine is controlled by a computer board, and the system is fully enclosed. The four-bar linkage system adopts imported pressure bearing connection, which effectively solves the problem of the side shift of the vacuum chamber.

Vacuum packaging is to evacuate the vacuum packaging bag, and then seal it to form a certain degree of vacuum in the bag, so that the packaged items can achieve the purpose of oxygen insulation, freshness, moisture, mildew, rust, insect, and pollution prevention. Effectively extend its shelf life and facilitate storage and transportation.

Working principle

Vacuum packaging machine, just need to press the vacuum cover complete after vacuum, sealing, cooling and exhaust in terms of the process.

The vacuum packaging or vacuum gas items can prevent oxidation , mildew and bug eat bymoth,damp,extended product storage period.

Configuration

1.Imported vacuum pump has the characteristics of waterproof, dustproof and accurate memory

2.New heating device, imported heating strip, isolation cloth

3.The material of the whole machine is 304 stainless steel, the working table and the table plate are 6mm thick

4.The equipment has mobile and fixed brakes

5.The equipment can be adjusted in multiple angles.