Factory Price Potato Finger Chips Machine - MULTI-LAYER CONTINUOUS DRYING LINE – INCHOI

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Food Vacuum Packing Machine, Sterilization Of Food Products, Basket Washing Machine, The team of our company along with the use of cutting-edge technologies delivers impeccable top quality products supremely adored and appreciated by our shoppers worldwide.

Bear "Customer first, Quality first" in mind, we work closely with our customers and provide them with efficient and professional services for Food Vacuum Packing Machine, Sterilization Of Food Products, Basket Washing Machine, The team of our company along with the use of cutting-edge technologies delivers impeccable top quality products supremely adored and appreciated by our shoppers worldwide. Factory Price Potato Finger Chips Machine - MULTI-LAYER CONTINUOUS DRYING LINE – INCHOI Detail:

Description

This machine is a continuous penetrating flow drying equipment applied for drying pieces strip and particles state materials with good ventilation. The machine is suitable for the materials such as dewatering vegetable, herbal medicine of traditional Chinese medicine and others, for which the water contents are high and high drying temperature is not allowed. The machine owns the advantages, of fast drying speed, high evaporation capacity and good product quality.The dewatered & filtered cake state paste material should be made into particles or strips before drying process.

Principle

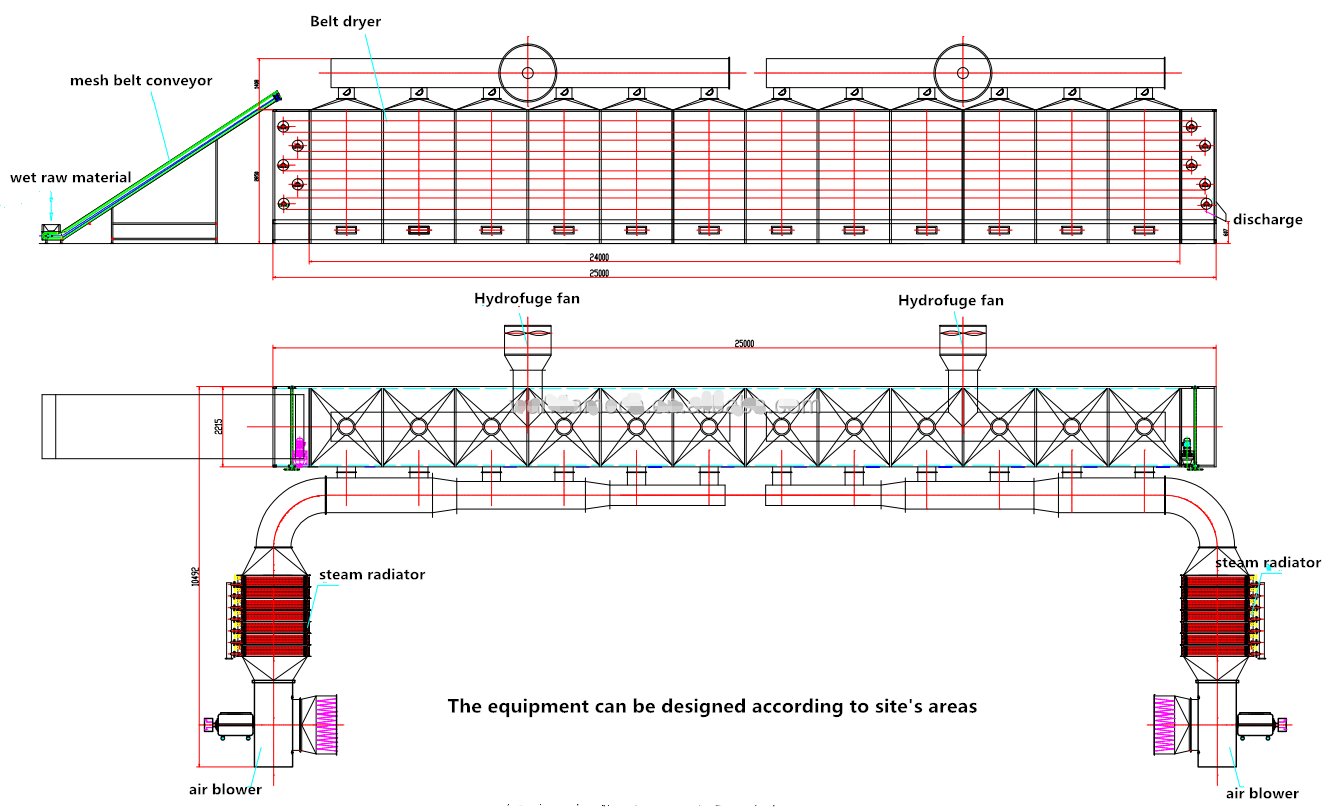

The materials are uniformly distributed on the mesh belt by the material feeder. The mesh belt generally adopts 12-60 mesh stainless steel mesh and it is drawn by a transmission device and move inside the dryer . The dryer is composed of several sections. For each section, the hot air is circulated separately. Part of exhausted gas is exhausted by a special moisture exhaust blower. The waste gas is controlled by an adjustment valve. The hot air passes through the mesh-belt covered with bring water material away. The mesh-belt moves slowly, running speed can be freely adjusted according to the material property. The final products after the drying process will fall into the material collector continuously. The top and low circulation units can be freely equipped according to the user’s requirements. The number of section might be selected according to the production demands.

Features

1 Amount of air, heating temperature, time of material sticking on the belt and velocity of feeding material can be adjusted in order to obtain the best drying effect.

2 Equipment’s con gyration is very excellent. It can use the netlike belt washing system and cooling raw material system.

3 Hot air can be circularly applied, the energy is greatly saved.

4 Unique air dividing device, it makes hot air distribute uniformly; this can guarantee products’ quality.

5 Heating source can be selected from steam, conducting heat oil, electricity, and coal furnace and oil burner

Technical advantages

1) Wide applications: The residence/drying time is adjustable from 15 minutes to 120minutes which makes it flexible to dry various kinds of raw material.

2) Energy-saving: Different types of hot air flow pattern and well insulated drying chamber can considerably reduce heat loss. Hot air circulation can be designed for energy-saving.

3) Uniform drying: The specially designed hot air distributor and drying zones can make sure uniform air flow in side the whole drying chamber to guarantee uniform drying.

4) Easy operation and maintenance: The whole drying system is highly automatic. The simple but practical design can not only reduce production cost but also maintenance and repair cost.

5) Flexible heat source: The heat source for drying can steam, electricity, hot water, thermal oil or oil/gas/coal/biomass fired hot air generator. We can design and engineer different heat source according to customer’s actual conditions.

6) Different types and layers of mesh belt are vailable based on specific raw material and drying conditions.

Main features

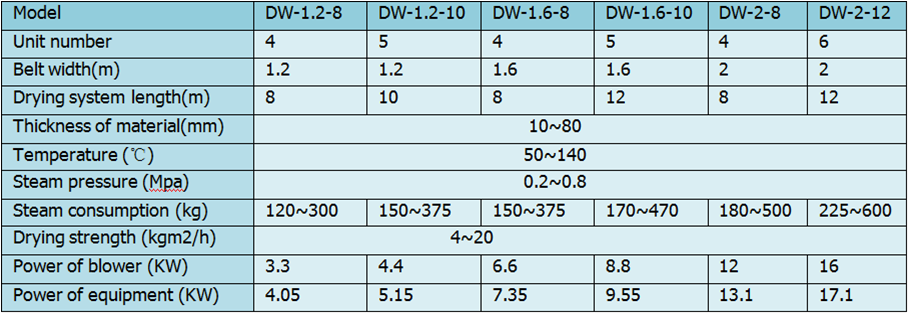

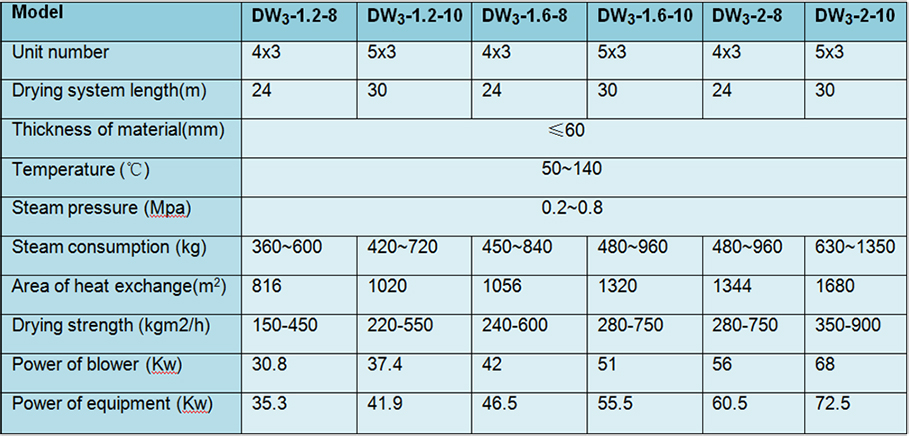

1. For drying or cooling of granular wet materials(1-20mm); 2. Drying belt area: 10-150 M2 3. Drying temperature: 60-180 degree C 4. Operation type: continuous 5. Heat source: steam, hot water, hot oil or oil/gas/coal/biomass hot air generator

6. Different types of air flow pattern, belt layer (1-5 layers) and mesh belt can be designed according to specific material

Product detail pictures:

Related Product Guide:

We insist over the principle of enhancement of 'High high quality, Efficiency, Sincerity and Down-to-earth working approach' to offer you with superb assistance of processing for Factory Price Potato Finger Chips Machine - MULTI-LAYER CONTINUOUS DRYING LINE – INCHOI , The product will supply to all over the world, such as: Tunisia, Berlin, Sudan, We hope we can establish long-term cooperation with all of the customers. And hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!