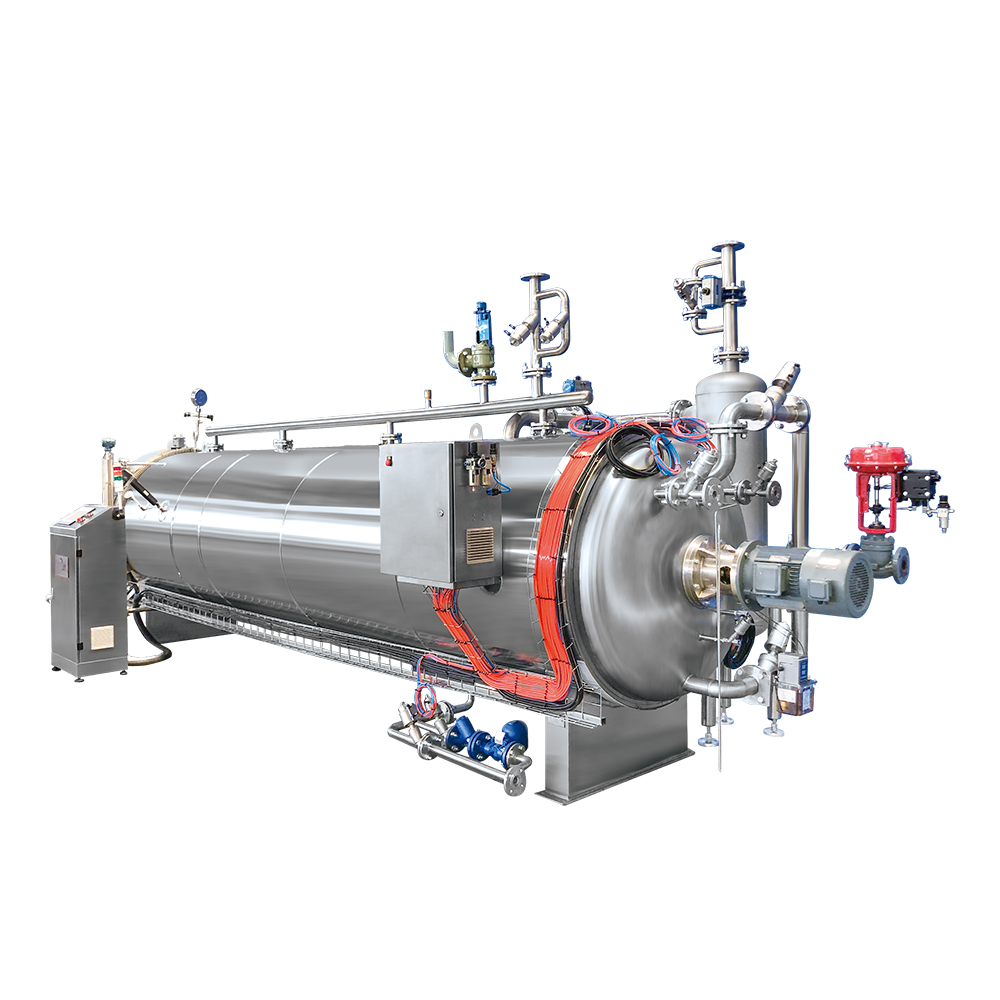

Factory wholesale Canning Retort Machine - Steam and AIR RETORT – INCHOI

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Dz 400 Vacuum Machine, Fish Bone Separator Machine, Iqf Tunnel Freezer Price, Welcomes all abroad close friends and retailers to ascertain collaboration with us. We are going to give you with genuine, high-quality and successful company to satisfy your requirements.

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, believe in the 1st and management the advanced" for Dz 400 Vacuum Machine, Fish Bone Separator Machine, Iqf Tunnel Freezer Price, Welcomes all abroad close friends and retailers to ascertain collaboration with us. We are going to give you with genuine, high-quality and successful company to satisfy your requirements. Factory wholesale Canning Retort Machine - Steam and AIR RETORT – INCHOI Detail:

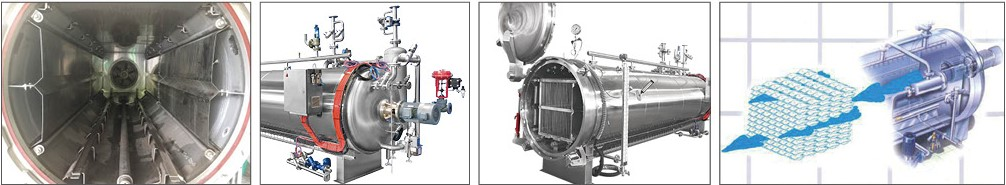

Applicable Scope:

Flexible packaging, bottled, tinplate cans (canned luncheon meat, canned tuna, etc.), standing bags, aluminum foil boxes, cups and bowls of snack foods, meat products, beverages and other high-temperature sterilization products.

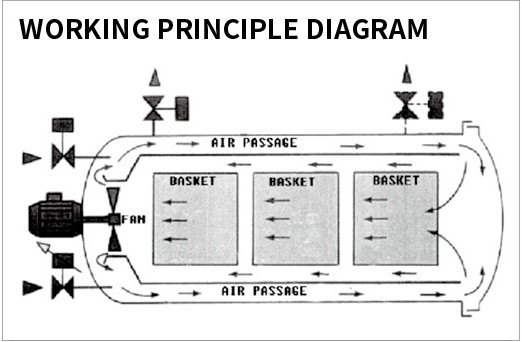

Working principle diagram:

Performance features:

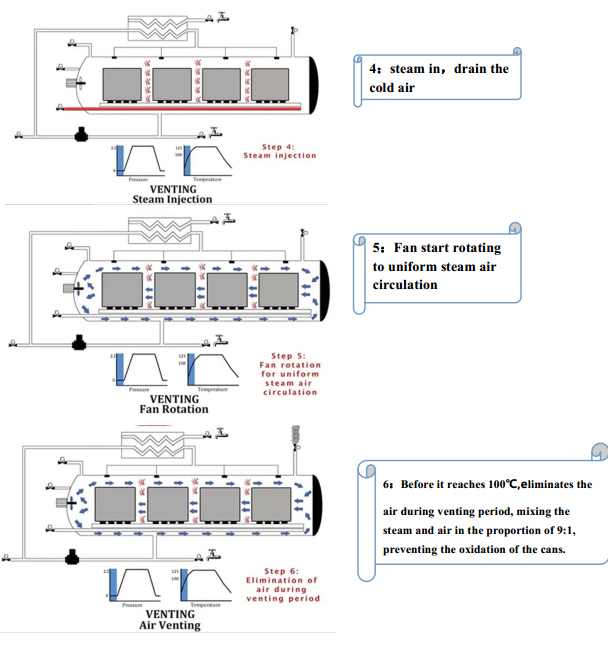

1. Compressed air is injected into the retort, and the turbo fan rotates to break the cold air mass , The mixture of steam and air is forced to circulate in the retort, for thorough sterilization and saving over 15% steam;

2. With dual pressure & temperature sensors and over pressure&temperature alarm function, it can better protect equipment and products;

3. Flexible control of pressure and temperature, realize cooling with counter pressure.

Advantage

●Accurate temperature control, excellent heat distribution

The temperature control module has up to 12 stages of temperature control, and the step or linearity can be selected according to different products and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.3℃. Steam enter the chamber while circulating fans ensures a proper temperature in the chamber. Sterilization is carried for preset temperature level & time.

●Rapid heating

No need to heat other media (such as hot water), the heating rate is very fast.

●Perfect pressure control, suitable for a variety of packaging forms

The pressure control module continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

●Save energy saving and protect environment

The steam is directly heated, no exhaust is needed, and the minimum steam loss.

Low noise, create a quiet and comfortable working environment.

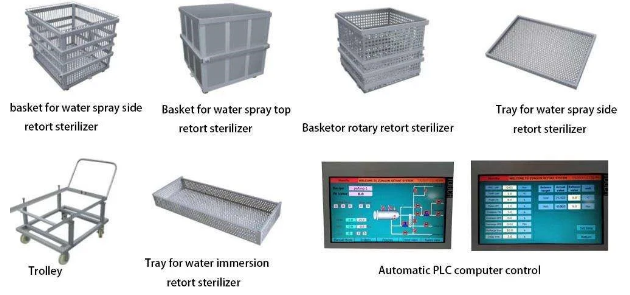

Product detail pictures:

Related Product Guide:

Our personnel are generally in the spirit of "continuous improvement and excellence", and together with the outstanding top quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for Factory wholesale Canning Retort Machine - Steam and AIR RETORT – INCHOI , The product will supply to all over the world, such as: Bhutan, Victoria, Swedish, Selling our products and solutions causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!