Fully automatic stretch thermoforming vacuum packaging machine

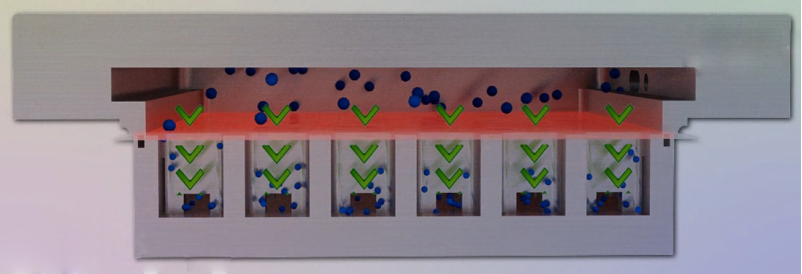

TUNNEL FREEZER

Product advantages:

1.304 Stainless steel frame structure

①The structure has high strength and is corrosion-resistant. The screw holes at each fixed position are processed with high-precision laser at one time to ensure the accuracy of assembly of each component and ensure the smooth operation of the whole machine.

②The most important feature is that it can infinitely expand new functions and reselect or add new functions at any time according to the product packaging form, such as: rounded corner packaging, easy tearing, double-sided molding, double-sided printing and marking, nitrogen-filled packaging and others new packaging.

③The stainless steel frame has strong resilience and is not easily deformed during transportation or machine operation, thus better maintaining the integrity of the equipment.

2.Forming device

The forming part is formed by positive pressure above + negative pressure below, and the film is formed evenly, and the thickness of the four corners of the forming can be guaranteed to be uniform.

3.Vacuum device:

Vacuum part joined the vacuum testing system to ensure everything went out of the vacuum chamber of the product to achieve the set vacuum values, such as a vacuum seal is bad (long seal aging phenomenon such as vacuum degree can not meet the requirements, equipment will not go to the next action, will always remain in the vacuum state, and the screen display failure.

4.Four-axis linkage lifting device

5.Electronic magnetic force pre-tightening device

The tension preloading device of the upper and lower membranes of the equipment adopts an advanced electronic magnetic preloading system, which has changed the current spring preloading and cylinder friction preloading methods on the market. Its main advantages are reflected in the following aspects:

6.Electrical System

The control system all uses Siemens electrical appliances, and the unified brand ensures the communication sensitivity of each component. The Siemens industrial computer system independently has temperature, vacuum, and automatic fault detection functions; it uses the most advanced high-inertia 2KW servo motor and high-precision servo driver of the Siemens brand. The system has large operating torque, resulting in accurate chain positioning, fast speed, and smooth operation.

7.Intelligent operating system

Touch screen operation, automatic program control, graphic display of the entire running status, automatic detection of the cause of failure, easy to operate and maintain the equipment.

8.Safety protection system

All transmission parts; parts with temperature; cutting and moving parts are equipped with protection devices, and magnetic contact switches are installed. Once the protection devices are not in place or the original machine protection devices are not in place, the machine will stop immediately.

9.Chain drive system

The chain drive system uses original imported chains, and the open wheels and chain boxes adopt new patented designs. This system has the following advantages:

① Wear resistance, life is higher than other similar products under the same use conditions.

②The patented open sprocket does no harm to the chain, and there will be no chain deformation and other phenomena, which prolongs the service life of the chain.The open sprocket makes the chain clip bear fully open film feeding simple, stable and easy to operate.

10.Waste film recycling system

The waste film collection device adopts an intelligent detection device, which is noiseless, has a simple and elegant appearance, has a total energy consumption of only 0.18kw/hour, and can automatically adjust the operating status according to the length of the waste film.

11.Color film automatic correction

Minimize the dependence on operators. (Workers only need to push the film into the air shaft to the bottom, no other adjustments are required, and the color film correction system can automatically adjust to the best position.)

12.Forming and heat sealing mold

All molds can be quickly replaced, and multiple sets of molds can be exchanged on a set of equipment to facilitate the packaging of multiple products.

13.Multifunctional slitting system

According to different products, it can realize round corner slitting, easy tearing, hanging holes, serrated slitting, overall punching and other applications, and the speed of cutter replacement is quick and easy.