Good quality Double Chamber Vacuum Packaging Machine - Ultra-high-speed freezing sleep(DOMIN)machine – INCHOI

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Impingement Tunnel Freezer, Retort Sterilization In Food Processing, Spiral Iqf, Being a young increasing organization, we might not the best, but we have been trying our best for being your very good partner.

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs of Impingement Tunnel Freezer, Retort Sterilization In Food Processing, Spiral Iqf, Being a young increasing organization, we might not the best, but we have been trying our best for being your very good partner. Good quality Double Chamber Vacuum Packaging Machine - Ultra-high-speed freezing sleep(DOMIN)machine – INCHOI Detail:

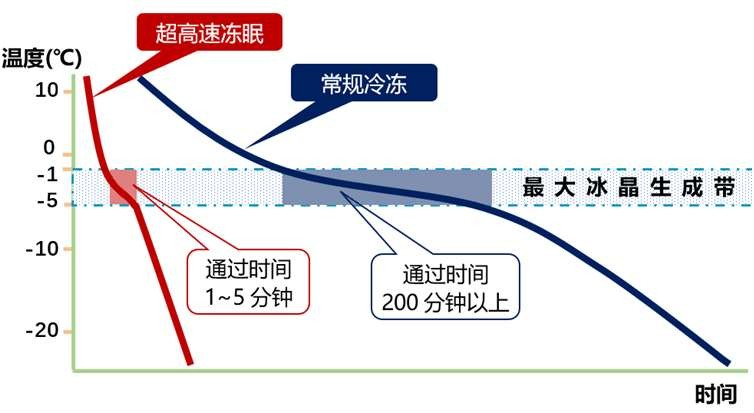

Ultra-high-speed freezing VS conventional freezing

—-Differences in Ice Crystal Nucleation Processes

Congelación ultrarrápida VS congelación convencional

—-Diferencias en los procesos de nucleación de cristales de hielo

Ultra-high-speed freezing

Congelación ultrarrápida

By adjusting crystallization thermodynamics and using electromagnetic field to control the process of ice crystal nucleation, the food can pass through the “maximum ice crystal formation zone” as shown in the figure above in the shortest time during freezing (usually between -1℃ and -5℃), and the water in the cells will form fine ice crystals after freezing, so as not to damage the food cells and tissues.

Al ajustar la termodinámica de cristalización y usar un campo electromagnético para controlar el proceso de nucleación de cristales de hielo, la comida puede pasar a través de la “zona máxima de formación de cristales de hielo” como se muestra en la figura anterior en el menor tiempo posible durante la congelación (generalmente entre -1 ℃ y – 5℃), y el agua en las células formará cristales de hielo finos después de la congelación, para no dañar las células y los tejidos de los alimentos.

Conventional freezing (conventional techniques such as air cooling)

Congelación convencional (técnicas convencionales como el enfriamiento por aire)

Freezing speed is slow, through the “maximum ice crystal formation zone” for a long time, the size of the ice crystals formed is large, the cells are punctured by the ice crystals, the tissue is destroyed in a large area, and the loss of umami juice after thawing.

La velocidad de congelación es lenta, a través de la “zona máxima de formación de cristales de hielo” durante mucho tiempo, el tamaño de los cristales de hielo formados es grande, los cristales de hielo perforan las células, el tejido se destruye en un área grande y la pérdida de jugo de umami después de descongelar.

Cells before freeze

Células antes de congelar

Cells after ultra-high-speed freezing

Células después de congelación ultrarrápida

Tiny ice

crystals

have no

broken cells

Los diminutos

cristales

de hielo no tienen células rotas.

La congelación a ultra alta velocidad forma diminutos cristales de hielo en las células, para no dañar las células y los tejidos de los alimentos.

Ultra-high-speed freezing forms tiny ice crystals in the cells, so as not to damage the cells and tissues of the food.

Slowly frozen (air cooled) cells

Células congeladas lentamente (enfriadas por aire)

large ice crystals

Damaged cell

Célula dañada

La velocidad de congelación es lenta, a través de la “zona máxima de formación de cristales de hielo” durante mucho tiempo, el tamaño de los cristales de hielo formados es grande, los cristales de hielo perforan las células, el tejido se destruye en un área grande y la pérdida de jugo de umami después de descongelar.

『Comparison of thawing effect after frozen sleep』

Comparación del efecto de descongelación después del Domin congelación

Compare results

Resultados de

comparación

1.The freezing speed is more than 40 times that of air cooling and more than 2 times that of liquid nitrogen freezing。

La velocidad de congelación es más de 40 veces mayor que la del enfriamiento por aire y más de 2 veces mayor que la del congelamiento con nitrógeno líquido.

2.Frozen sleep food after thawing, food to maintain fresh state, no juice flow, quality, color and taste far higher than air cooling and other refrigeration equipment

Alimentos congelados por DOMIN tecnología, después de descongelarlos, los alimentos pueden mantener el estado fresco, sin flujo de jugo, calidad, color y sabor mucho más altos que el enfriamiento por aire y otros equipos de refrigeración

Product detail pictures:

Related Product Guide:

Our company aims to operating faithfully, serving to all of our customers , and working in new technology and new machine constantly for Good quality Double Chamber Vacuum Packaging Machine - Ultra-high-speed freezing sleep(DOMIN)machine – INCHOI , The product will supply to all over the world, such as: Hamburg, Poland, Roman, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.