Hot New Products Pasteurization Line - Electric/gas deep Frying machine – INCHOI

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Bubble Washing Machine, Deep Fryer Machine, French Fry Making Machine, We have been wanting forwards to creating long-term company interactions with around the world shoppers.

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for Bubble Washing Machine, Deep Fryer Machine, French Fry Making Machine, We have been wanting forwards to creating long-term company interactions with around the world shoppers. Hot New Products Pasteurization Line - Electric/gas deep Frying machine – INCHOI Detail:

Video

Application

The machine is used for frying nuts, potato chips, French fries, plantain/banana chips, chicken drumstick, fish cutlet, chicken cutlet, peanuts, puffed snacks, meat pie, carrot, onion rings, sweet potato, beans etc. It can keep the nutrition to the greatest extent for the food.

Detail

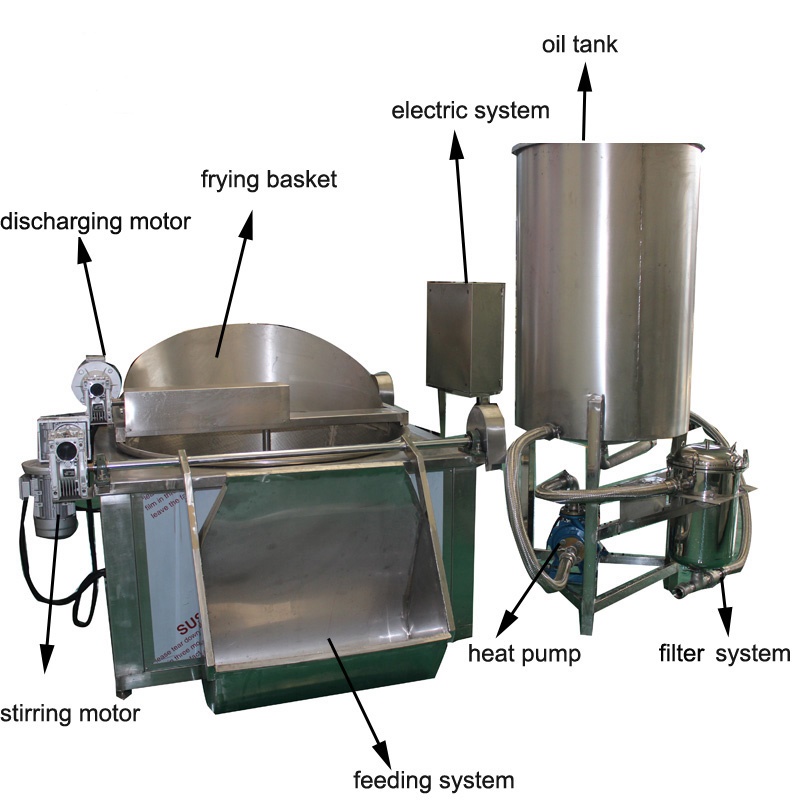

1. It adopts digital temperature control and is accompanied by a high-temperature upper limit power-off function, and the temperature rise is absolutely safe.

2. The oil-water mixing process design is adopted. The food residues produced during the frying process can sink into the lower funnel through the filtration of water and be discharged through the sewage outlet, which not only achieves the function of filtering oil but also does not waste oil.

3. The advanced and efficient heating system, and the oil tank adopts heat preservation technology, which not only saves energy but also improves work efficiency.

4. The upper and lower double-layer mesh belts are designed to keep the frying color uniform when the product floats during the frying process, and will not cause uneven frying of the floating food.

Parameters of Commercial Egg Frying Machine

|

Model |

Heating Type |

Dimension(mm) |

Weight(kg) |

Fry basket size |

Oil discharge |

Air consumption |

Power |

|

YZE-1000 |

Electric |

1500*1400*1700 |

400 |

φ1000*400 |

320 |

|

Stir 0.37KW |

|

YZE-1200 |

Electric |

1700*1500*1700 |

500 |

φ1200*400 |

460 |

|

Stir 0.37KW |

|

YZE-1500 |

Electric |

2000*1800*1700 |

780 |

φ1500*400 |

720 |

|

Stir 0.55KW |

|

YZG-1000 |

Gas |

2100*1400*1700 |

700 |

φ1000*400 |

320 |

12cube |

Stir 0.37KW |

|

YZG-1200 |

Gas |

2300*1500*1700 |

800 |

φ1200*400 |

460 |

23cube |

Stir 0.37KW |

|

YZG-1500 |

Gas |

2600*1800*1700 |

1080 |

φ1500*400 |

720 |

23cube |

Stir 0.55KW |

|

Model |

Heating Type |

Dimension(mm) |

Weight(kg) |

Fry basket size |

Oil discharge |

Air consumption |

Power |

|

YZE-1000 |

Electric |

1500*1400*1700 |

400 |

φ1000*400 |

320 |

|

Stir 0.37KW |

|

YZE-1200 |

Electric |

1700*1500*1700 |

500 |

φ1200*400 |

460 |

|

Stir 0.37KW |

|

YZE-1500 |

Electric |

2000*1800*1700 |

780 |

φ1500*400 |

720 |

|

Stir 0.55KW |

|

YZG-1000 |

Gas |

2100*1400*1700 |

700 |

φ1000*400 |

320 |

12cube |

Stir 0.37KW |

|

YZG-1200 |

Gas |

2300*1500*1700 |

800 |

φ1200*400 |

460 |

23cube |

Stir 0.37KW |

|

YZG-1500 |

Gas |

2600*1800*1700 |

1080 |

φ1500*400 |

720 |

23cube |

Stir 0.55KW |

Industrial Batch Gas Deep Fryer With Temperature Control Specifications

3.1 Auto time and temperature control, auto mixing, auto discharging, auto deoiling.

3.2 Overtemperature protection.

3.3 Temperature from 0~300°C adjustable.

3.4 PLC Control system

3.5 Emergency stop, short circuit and grouding protection.

DESCRIPTION

1. The inner frying area of the fryer is designed with a small cone-shaped hemispherical shape, which greatly reduces the ineffective oiling while ensuring that the area of the frying area is not reduced, and saves 50% of the original frying oil.

2. The fryer can be equipped with an oil tank for storing oil. The oil tank serves two functions. One is that the staff will pump the oil into the oil tank through the oil pump after the end of the work day to facilitate the storage of oil, and the other is that the oil will be stored overnight After the precipitation of the oil, a lot of very viscous oil will be deposited in the conical groove at the bottom of the oil tank. This part of the oil can be discharged through the oil drain valve under the oil tank, which will reduce the oil residue and reduce the acid value. Produce, thereby increasing the life cycle of the oil.

3. Functions: automatic mixing, automatic feeding, automatic discharging, automatic temperature control, high temperature alarm, automatic slag scraping.

Name: Automatic feeding system

Advantage characteristics:

The automatic feeding system avoids splashing oil droplets scalding workers in the process of putting materials, enhances the safety of workers’ operation, and improves production efficiency.

Name: Planetary automatic stirring system

Advantage characteristics:

The automatic stirring system simulates manual stirring so that the product can be stirred evenly in the frying process to ensure the uniformity of the product.

Name: Automatic discharging system

Advantage characteristics:

It reduces the workload of workers, ensures the consistency of the products in time, and improves the quality of products.

Machine Parts

Advantage characteristics:

The digital control system adopts button operation, which is easy for workers to manipulate the fryer flexibly. The control cabinet is made of stainless steel, with good waterproof and heat dissipation effect.

Product detail pictures:

Related Product Guide:

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Hot New Products Pasteurization Line - Electric/gas deep Frying machine – INCHOI , The product will supply to all over the world, such as: Berlin, Croatia, San Diego, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.