Manufacturer for Potato Chips Processing Line - Automatic fruit and vegetable crisp chips puffing production line – INCHOI

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Autoclave Retort, Automatic Fryer Machine Price, Individual Quick Freezing Process, We never stop improving our technique and quality to keep up with the development trend of this industry and meet your satisfaction well. If you are interested in our products, please contact us freely.

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Autoclave Retort, Automatic Fryer Machine Price, Individual Quick Freezing Process, We never stop improving our technique and quality to keep up with the development trend of this industry and meet your satisfaction well. If you are interested in our products, please contact us freely. Manufacturer for Potato Chips Processing Line - Automatic fruit and vegetable crisp chips puffing production line – INCHOI Detail:

Equipment Introduction:

◆Varying temperature and pressure difference puffing, as the name show is basis on the principle of popcorn, put the pre-treated fruit and vegetable into the pressure pot, evaporate the inner moisture by steam heating to achieve the same temperature between inner and outer part of the material, at the same time generate vapor to lead pressing continuously rise and set a pressure value, when reach the target pressure ,flashily release pressure to evaporate the inner moisture of the fruit and vegetable ,there will be a huge vapor pressure difference in the inner part of the material to make the cell and organization puff .Finally through vacuum low temperature drying to make the inner moisture content under 5%, take out the fruit and vegetable crisp chips after cooling .This equipment can maintain the nutritional content and fresh flavor of fruits and vegetable, complete dehydration, crispy texture, full shape and uniform expansion.

Applicable Scope:

◆With appropriate production technology, it can process a variety of fruits and vegetables, such as mulberry, waxberry, raspberry, blueberry, chickpea, gold pear, mango, apples, dates, kiwis, dragon fruits, blackcurrant, cantaloup, wolfberry, pineapple, bananas , Kelp, strawberries, tomatoes, carrots, eggplant, mushrooms, garlic, and so on.

Equipment feature:

◆Maximally keep the nutrient content, micro-element and mineral element of the fruit and vegetable during processing. No noise ,no pollution, low energy consumption during production, and meet environment protection requirements and food hygiene standards. Stable performance, simple operation, convenient maintenance, safe and efficient.

Product Description

The vacuum low temperature puffing system is mainly composed of a pressure tank and a vacuum tank which is 5-10 times larger than the pressure tank. After pretreatment, the fruit and vegetable raw materials were dried to moisture content of 15%-25% (the water content of different fruits and vegetables is different). Then, fruits and vegetables are placed in a pressure tank. By heating and pressing, the evaporation and flashing of water in fruits and vegetables suddenly to achieve the purpose of expansion of fruit and vegetable cells.

Machine Parameter

|

Model |

PHJ-600-2 |

PHJ-1200-2 |

PHJ-1200-4 |

|

Parameter |

|||

|

Material |

Food grade 304 stainless steel |

Food grade 304 stainless steel |

Food grade 304 stainless steel |

|

Vacuum pot size |

3600*1000mm(Diameter) |

5500*1800mm(Diameter) |

10000*1800mm(Diameter) |

|

Vacuum pot plate thickness |

8mm |

8mm |

8mm |

|

Flash evaporation pot size |

1650*600mm(Diameter) |

2800*1200mm(Diameter) |

2800*1200mm(Diameter) |

|

Flash evaporation pot thickness |

6mm |

6mm |

6mm |

|

Heating mode |

Steam |

Steam |

Steam |

|

Steam consumption |

60kg/h |

160kg/h |

320kg/h |

|

Flash evaporation pot door open mode |

Manually |

Manually |

Manually |

|

Capacity |

3kg/ pot for material |

40kg/ pot for material |

40kg/ pot for material |

|

Processing time |

According to the products |

According to the products |

According to the products |

|

Vacuum pot cooling mode |

Water cooling |

Water cooling |

Water cooling |

|

Thermal insulation material |

Rock wool |

Rock wool |

Rock wool |

|

Thickness of insulation layer |

50mm |

50mm |

50mm |

|

Vacuum pump power |

14kw/set 1set |

19kw/set 1set |

19kw/set 2set |

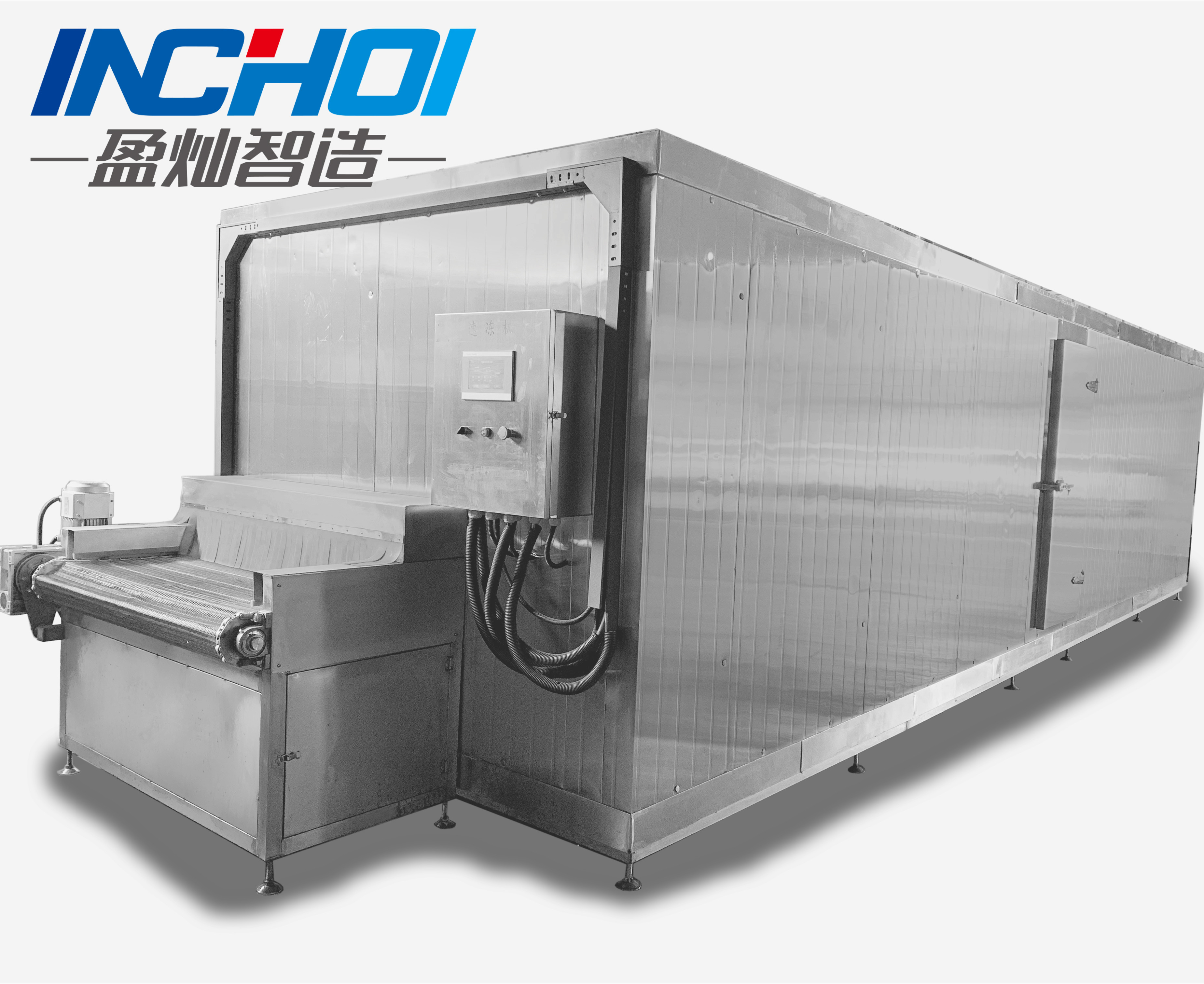

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Manufacturer for Potato Chips Processing Line - Automatic fruit and vegetable crisp chips puffing production line – INCHOI , The product will supply to all over the world, such as: St. Petersburg, Croatia, Sri Lanka, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.