Manufacturer for Potato Chips Processing Line - Vf-Intelligent Vacuum Frying Machine – INCHOI

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Drying Line, Octofrost Tunnel, Retort Machine In Food Industry, We will supply high-quality solutions and fantastic companies at aggressive charges. Start benefiting from our comprehensive providers by contacting us today.

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Drying Line, Octofrost Tunnel, Retort Machine In Food Industry, We will supply high-quality solutions and fantastic companies at aggressive charges. Start benefiting from our comprehensive providers by contacting us today. Manufacturer for Potato Chips Processing Line - Vf-Intelligent Vacuum Frying Machine – INCHOI Detail:

Advantages

- Prevent the deterioration of edible fats and oils, improve the repeated utilization of oil, Reduce costs, the oil content of general fried food is as high as 40%-50%, The oil content of vacuum frying is 5%-10%.

- Vacuum low temperature oil bath dehydration can make fried food not easy to fade discoloration and browning can maintain the color of the raw material itself.

- The vacuum frying technology can well preserve the fragrance of the raw material itself.

- Through low-temperature frying, the original taste of the product is protected.

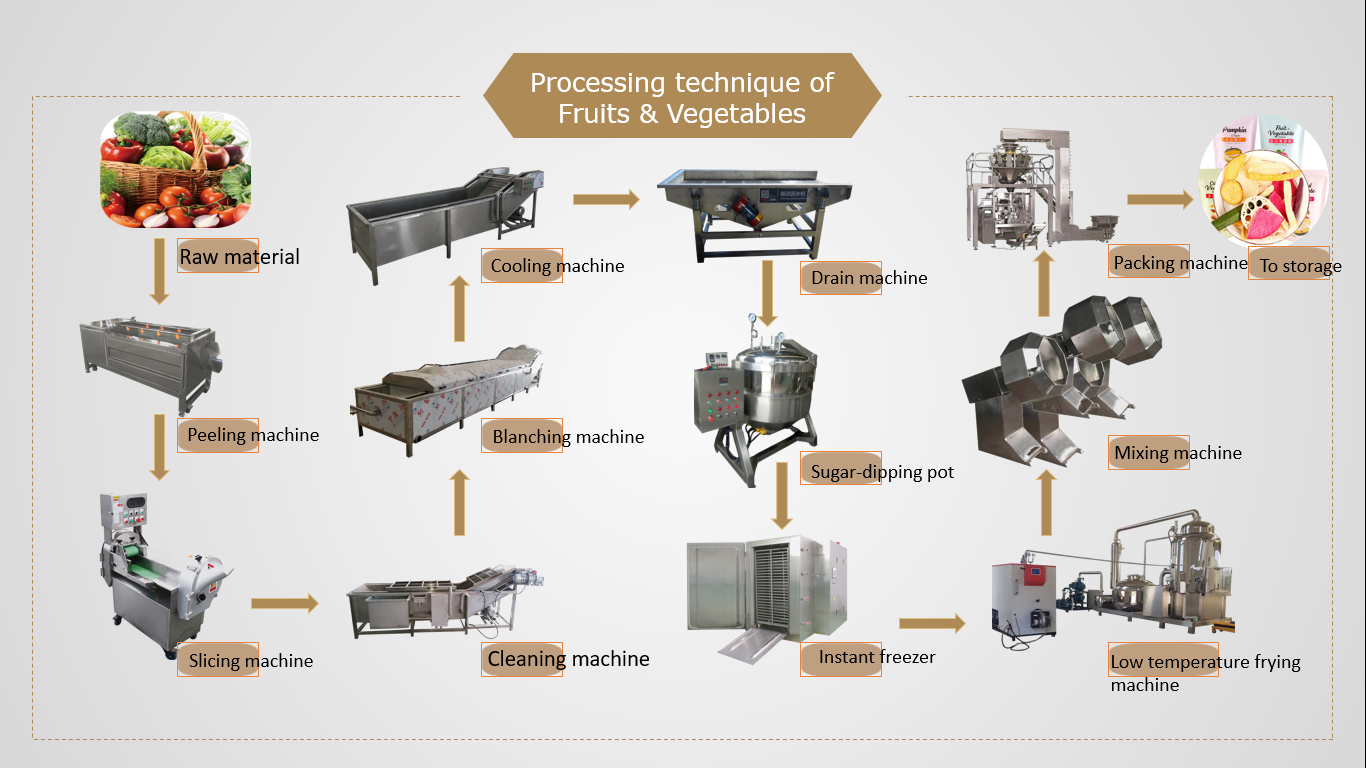

Process flow

Raw material → screening → cleaning → slicing (cutting) → blanching (color protection) → draining → freezing → thawing → dipping (vacuum impregnation) → cleaning → draining → vacuum frying → vacuum deoiling → seasoning → product packaging → storage

Technical parameters

| Parameter/Model | VF-1200 | |

| Processing capacity (raw material kg/time) | 2400-300kg | |

| Processing time(min/time) | About 50-180min | |

| Limit vacuum degree(MPA) | -0.093≈-0.098mpa | |

| Oil temperature(℃) | 80-120 | |

| Heating Source | Headting Source | steam |

| Steam Consumption(kg/h) | 300 | |

| Steam Pressure(MPA) | 0.4-1.5 | |

| Main heating methods | External circulation of oil pump | |

| Degreasing Speed n/min | 0~400 | |

| Cooling water volume(T/H) | 15 | |

| Power Supply | Elecricity Ststem | 380V |

| Total Power(kw) | 37kw | |

| Equipment group covers an area of(mm) | 5800*2200*3800mm | |

| Fryer basket quantity(pcs) | 1 piece | |

| Fryer basket sise(mm) | Diameter 1200*600mm | |

| Oil tank storage(L) for recycling | 2500L | |

Overview of vacuum frying

Nutrition, convenience, safety and green are the development trend of food production. Fruit and vegetable chips with unique flavor and pure nature are popular in developed countries and regions such as Europe, America, Australia, Japan, Hong Kong and Taiwan. In China, with the continuous improvement of people’s living standards, people are increasingly pursuing natural flavor food. In developed cities such as Beijing, Shanghai, Yunnan, Shaanxi, Inner Mongolia, Tibet, Tianjin and so on, they have been warmly pursued by consumers. There is no urgent demand for products.

(1) Principle of vacuum low temperature frying dehydration and drying:

Fruit and vegetable chips are made of fresh fruits and vegetables as the main raw materials, edible vegetable oil as the hot medium, and vacuum low-temperature frying (VF vacuum)Fryer) and other advanced technologies can quickly dehydrate and dry fruits and vegetables with low water content in a very short period of time, with low oil content, crisp but not greasy, preserving the original shape, color, aroma and taste of fruits and vegetables, and rich in vitamins, minerals, fibers and other nutrients, with low sugar, low salt, low fat, low heat and other characteristics.

Para fabricar chips de frutas y verduras, frutas y verduras frescas son materiales principales, aceite vegetal es el medio de calentamiento, y la freidora al vacío de baja-temperatura (Freidora al vacío VF) puede deshidratar y secar rápidamente frutas y verduras con bajo contenido de agua, en un período de tiempo muy corto, y con muy bajo contenido de aceite, los chips son crujientes pero no grasientos, se mantiene su forma, color, sabor de las frutas y verduras, además, se contiene abundante de vitaminas, minerales, fiebres y otras nutriciones, y poco azúcar, sal, grasa, caloría y otras características.

(2) Vacuum low temperature frying applicable to food range:

1Fruits: apples, bananas, macaques, pineapples, winter jujubes, strawberries, jackfruit, etc.

2Vegetables: such as carrot, radish, sweet potato, pumpkin, garlic, onion, edible fungus, wax gourd, okra, etc.

3Meat: such as beef, fish fillet, shrimp, octopus, etc.

(3) Vacuum frying process flow:

Raw materials → screening → cleaning → slicing (cutting) → cyaniding (color protection) → drainage → freezing → vacuum frying → vacuum de-oiling → seasoning → product packaging → warehousing.

Detailed description of the equipment

Our company introduces a complete set of foreign vacuum low-temperature frying technology to produce vacuum frying machine from a high starting point. The technology is in a leading position in the same industry in China. The vacuum frying equipment produced by our company belongs to intermittent type.

(2) Equipment configuration and configuration list

The composition system of vacuum frying machine is as follows

Vacuum frying kettle, oil circulation heating system, vacuum system, water vapor capture system, automatic oil removal system, electrical control system.

(1) The vacuum system consists of vacuum kettle, water vapor trap condenser, water ring vacuum pump, water cooling system and related valves and pipelines. It is used to vacuum the system and keep high vacuum during frying.

(2) The oil steam heating system is composed of stop valve, steam solenoid valve, safety valve and related valves, pipelines and monitoring instruments. For heating cooking oil.

(3) The electric control system is composed of internationally famous PLC, touch screen and low voltage electrical apparatus, which is used for system protection and automatic control.

(4) The de-oiling system is used for vacuum centrifugal de-oiling at the end of frying to reduce the oil content of fried food.

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for Manufacturer for Potato Chips Processing Line - Vf-Intelligent Vacuum Frying Machine – INCHOI , The product will supply to all over the world, such as: Honduras, Korea, Norwegian, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.