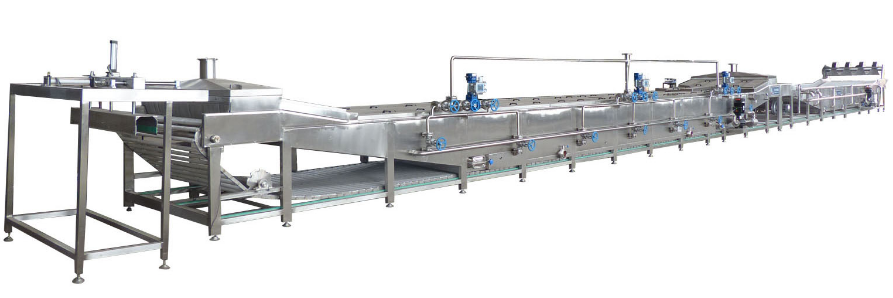

Manufacturer of Industrial Fryer Machine - PASTEURIZATION/COOLING LINE – INCHOI

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We've been an energetic corporation with wide market for Retort Process In Canning, Autoclave Suppliers, Frigoscandia Iqf, Quality is factory's lifestyle , Focus on customers' demand could be the source of corporation survival and advancement, We adhere to honesty and great faith operating attitude, looking ahead on your coming !

owing to excellent assistance, a variety of top of the range items, aggressive costs and efficient delivery, we take pleasure in a very good standing amongst our shoppers. We've been an energetic corporation with wide market for Retort Process In Canning, Autoclave Suppliers, Frigoscandia Iqf, Quality is factory's lifestyle , Focus on customers' demand could be the source of corporation survival and advancement, We adhere to honesty and great faith operating attitude, looking ahead on your coming ! Manufacturer of Industrial Fryer Machine - PASTEURIZATION/COOLING LINE – INCHOI Detail:

Product Desciption

The equipment is made of high quality stainless steel and advanced control instruments. It has beautiful appearance, convenient operation and maintenance. it has low labor intensity, less manpower, high degree of self-control, and the temperature can be automatically adjusted within 98 °C. The temperature difference between the upper and lower layers is small, and the product quality is easy to control.

This product is in full compliance with quality certification requirements, is hygienic and efficient, and is an ideal equipment for the food processing industry. The equipment adopts double-layer mesh belt setting, which effectively presses the material into the water completely, so that the material is sterilized evenly.

The transmission speed of the mesh belt is adjustable. The equipment is equipped with a pneumatic angle seat valve. When the temperature inside the sterilizer is lowered, the steam is automatically replenished. When the temperature inside the sterilizer reaches the set temperature, it is automatically turned off to save energy. The machine has the characteristics of good temperature control, high efficiency and labor saving.

The equipment is equipped with a circulation pump to allow the water in the sterilizer to flow to ensure a uniform water temperature. The outer tank body is provided with an insulation layer to reduce heat loss and save energy. A steam outlet is provided at the upper end of the device, and excess exhaust gas is discharged from the exhaust port. The upper cover can be lifted to clean the inside of the body, and the lower end is provided with a sewage outlet for convenient sewage discharge and cleanness. After the material is sterilized, it is transported to the cooler through the mesh belt to cool the entire pasteurization process.

|

Item |

Parameter |

|

Sterilizing time |

10-40min |

|

Cooling mode |

Natural temperature water or chiller cooling water |

|

Belt width |

800mm |

|

Sterilizing temperature |

60-95 ℃ |

|

Capacity |

Customized |

|

Working speed |

Stepless speed regulation |

|

Power |

5.5-120kw |

|

Voltage |

380V/ Customized |

|

Machine size |

7000*800*1500mm |

|

Note |

This machine can be customized |

The equipment adopts preheating-sterilization–pre-cooling–cooling four sections and spraying and sterilizing the objects in the four directions of up, down, left and right, the sterilization speed of different products is different, the temperature of the equipment can be arbitrarily set, automatic control, Maintain constant temperature and automatic recording;

The pasteurization machine is made of food grade 304 stainless steel except for bearings and motors, and the mesh belt is the most ideal equipment in China.

Equipment Features

● The machine is made of stainless steel, in line with European CE marking;

● Pasteurizing temperature is adjustable within 98C°. and temperature is uniform so as to ensure consistent product quality.

● Machine uses qualified governor, stepping conveyor speed with high accuracy;

Key parts of the machine we choose qualified and certificated spare parts to ensure the quality and longevity of the machine ;

● PLC computer control, the operation is easy, convenient and flexible;

● Labor saving, increase productivity, ensure the consistence of product taste and color, and maintain the original nutrients;

● You can choose PP, SS mesh ,SS plate as your transport material based on your product.

equipment introduction:

◆Temperature and speed can be set according to process requirements.

◆Use steam heating to save energy.

◆The sterilization temperature is uniform, and the product quality is the same.

◆Low-temperature sterilization within 98℃, food nutrients will not be destroyed, and the original taste and color will be maintained.

◆The machine runs smoothly, the conveying mesh belt (chain plate) has high strength, small flexibility, not easy to deform, and easy to maintain.

◆A cooler can be added to cool the product to room temperature and quickly enter the next process.

|

Bottle /can pasteurization machine |

|

| Apply to |

Bottled beverage /cans after filling |

| Pasteurization time |

10~60min |

| Pasteurizing temperature |

≤ 98℃ adjustable |

| Conveyor width |

600 / 800/ 1000mm |

| Heating method |

Electric heating / steam heating |

| Capacity |

100~5000 bottle/h |

|

Bag packaging pasteurization machine |

|

| Apply to |

Bagged food after filling |

| Pasteurization time |

10~60min |

| Pasteurizing temperature |

≤ 98℃ adjustable |

| Conveyor width |

600 / 800/ 1000mm |

| Heating method |

Electric heating / steam heating |

| Capacity |

100~5000 bottle/h |

A double-deck pasteurizer is used for the narrowly workshop which the space are limited. This Machine will save your space in the workshop and all the function of the pasteurizing ability are same as standard one .

Continuously pasteurize packed Jelly, mustard, pickled cabbage, milk, canned food, condiments, meat and poultry food bags, cans, bottles, and then automatically cooling, drying and packing in cartons.

Product detail pictures:

Related Product Guide:

Good quality To start with,and Purchaser Supreme is our guideline to offer the top service to our customers.Presently, we've been seeking our best to be amongst the top exporters inside our industry to fulfill consumers extra need to have for Manufacturer of Industrial Fryer Machine - PASTEURIZATION/COOLING LINE – INCHOI , The product will supply to all over the world, such as: Peru, Romania, Madras, Although continuous opportunity, we have now now developed serious a friendly relationship with many oversea merchants, such as ones through Virginia. We securely assume that the merchandise regarding t shirt printer machine is often good through a great number of having its good quality and also cost.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.