OEM/ODM Manufacturer Autoclave In Food Industry - Horizontal vortex spiral washing machine – INCHOI

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Chips Deep Fryer Machine, Sterilizing Solution, Dzq Vacuum Packer, We're going to endeavor to maintain our fantastic track record as the very best products supplier in the planet. When you've got any questions or reviews, you should get in touch with with us freely.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Chips Deep Fryer Machine, Sterilizing Solution, Dzq Vacuum Packer, We're going to endeavor to maintain our fantastic track record as the very best products supplier in the planet. When you've got any questions or reviews, you should get in touch with with us freely. OEM/ODM Manufacturer Autoclave In Food Industry - Horizontal vortex spiral washing machine – INCHOI Detail:

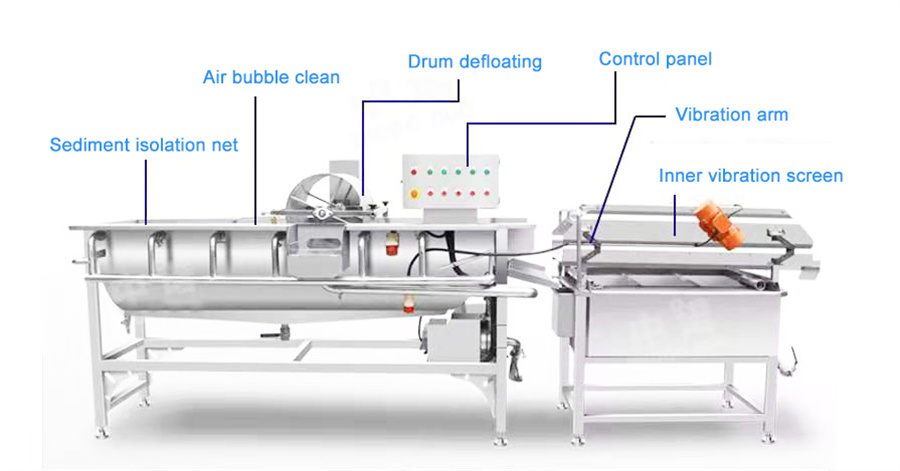

The unobstructed cylinder design avoids multiple collision damage during material cleaning; the ozone disinfection system effectively removes the toxicity of pesticide residues in fruits and vegetables and detergent residues; automatic water replenishment design, no need for manual water replenishment.

Equipment Introduction

First time horizontal vortex rough wash plus first time vibration to remove water wash to eliminate huddle phenomenon when washing vegetables without cutting by using traditional vortex spiral washing machine. High pressure bubble can separate the huddle vegetables efficiently to settle the problem that pure vortex washing machine can only wash materials which have be cut.

Note: Can Be Customized

Application

Horizontal vortex spiral washing machine is mainly used to wash leafy, rhizome vegetables and pickled fruit&vegetables such as Chinese cabbage, lettuce, spinach and pickled radish etc.

Characteristics

1) Ozone sterilization system can remove the residual pesticide and toxicity of detergent residues. Self-help filling water, without manual work.

2) Water level regulation, impurity concentration recovery device

3) Fast loading type roller device to remove impurity and insect: roller separates the impurity and insect from water surface then exhaust them through discharge port.

4)Automatic discharge system: Automatic continuous filtration, Automatically collect impurities, Realize water recycling utilization

5) High pressure bubble equipment: bubble washing system is installed in the body of the washing machine through pipe bracket, generate bubble in the water, add oxygen content in the water to maintain freshness of vegetables.

6) Vibration draining device: transmit light and heavy materials through adjust vibration frequency. Using low noise imported shock absorber block.

The multifunctional vortex cleaning machine adopts bubble water bath to clean, suitable for the cleaning of fruits, vegetables (fresh vegetables, pickled vegetables, fungus vegetables), aquatic products, and medicinal materials. The equipment can be customized according to the output size. The equipment is made of high-quality stainless steel, which meets the food hygiene standards. Equipped with a bubble generating device, the material is in a rolling state, and it has the effect of removing silt, dust and pesticide residues on the surface. The equipment is all made of stainless steel and is used to clean food.

The advantages of bubble cleaning + swirling vegetable washing machine. On the basis of traditional cyclone cleaning, a bubble cleaning design is added, and a high-pressure gas injection pipe is arranged at the bottom of the cylinder to eliminate the clumping phenomenon generated by the traditional cyclone vegetable washing machine when cleaning uncut vegetables. The high-pressure air bubbles can be separated into The group of vegetables solves the shortcomings of the pure swirling type, and the vegetable washing machine can only clean the materials after cutting. The exhaust pipe is equipped with a pressure relief valve to adjust the bubble strength when cleaning different materials. Flip cleaning + 16 high-pressure adjustable bubble vibration cleaning, double clean cleaning, whether it is whole vegetables or cut vegetables, shredded vegetables, eddy current vegetable washing machine can easily handle.

features

1. The cylinder body is made of SUS304 stainless steel plate, three-dimensional seamless analysis, rotation + bubble double cleaning, and ozone can be added to disinfect the pump system.

2. The water inlet and side of the water tank are equipped with water spray pipes, which are supplied by a high-pressure water pump. The water in the water tank generates a swirling state through the water spray pipe under the action of the water spray pipe.

3. The material rotates forward under the action of water flow, and the product: 36O degree swirling washing.

4. Material transportation is high-frequency vibration drainage, using high-frequency micro-vibration motors and imported high-frequency flexible springs.

5. There is a circulating water tank at the lower end of the vibrating screen, and a filtering device at the upper end of the circulating water tank, which can effectively filter out impurities.

6. The circulating water tank is equipped with an automatic water replenishment device. When the water level reaches the predetermined low level, the water is automatically held without manual water discharge.

Technical parameters

| Name | Parameter |

| Dimension | 4200×800mm (Diameter) |

| Total power | 9.67kw |

| Water consumption | 0.4MT/h |

| Material | 2.5mm food grade 304 stainless steel |

| Stainless steel centrifugal water pump | 2 sets 3kw/set |

| Vortex pump | 2.2kw |

| Vibration motor | 2sets 0.16kw/set |

| Slag discharge motor | 0.37kw |

| Drum motor | 0.18kw |

| Ozone generator | 0.6kw |

| Small water tank | 2mm food grade 304 stainless steel |

| Vibration sieve plate | Thickness: 2mm Hole Size: 3mm Material: food grade 304 stainless steel |

| Vibration buffer block | Imported from Switzerland |

| Bracket | 50×50×2mm food grade 304 stainless steel |

Product detail pictures:

Related Product Guide:

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for OEM/ODM Manufacturer Autoclave In Food Industry - Horizontal vortex spiral washing machine – INCHOI , The product will supply to all over the world, such as: Tunisia, Vietnam, Iran, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.