Renewable Design for Potato French Fry Machine - Air energy intelligent drying line – INCHOI

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Autoclave Food Preservation, Continuous Vacuum Packaging Machine, Retort Sterilizer, Welcome your enquiry, best service will be provided with full heart.

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Autoclave Food Preservation, Continuous Vacuum Packaging Machine, Retort Sterilizer, Welcome your enquiry, best service will be provided with full heart. Renewable Design for Potato French Fry Machine - Air energy intelligent drying line – INCHOI Detail:

Applicable Scope:

◆Deep processing of seafood, various agricultural products, flexible packaging food bags, snack foods, dates, nuts, medlar, apple slices, raisins, banana slices, preserved fruits, okra and Chinese herbal medicine.

Work Principle

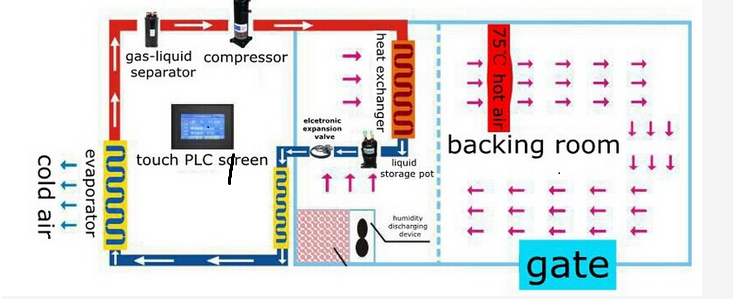

The product is conveyed by mesh belt. The hot air is pressurized through the heat exchanger with the strong current fan, and the hot air is blown into the drying machine body which running mesh belt. The hot air in the body is convective, direct current, up and down circulation, and then discharged by the upper humidity outlet, so as to complete the drying purpose.

Using food grade materials is safe, reliable and pollution-free. The conveying is stable and the speed is adjustable. The moving of the material with the conveyor belt can avoid damage to the conveyor. The noise is small, and is suitable for occasions with quieter working environment. The structure is simple and easy to maintain. The energy consumption is small and the cost of use is low. The machine is made of stainless steel The temperature and time can be adjusted according to the requirements. The machine is compact in structure, easy to operate and low error rate. The heating mode is Natural gas, which is especially suitable for continuous operation. The device adopts the manual temperature control system, which is uniform in heating, low in temperature and adjustable in temperature. It is suitable for drying different products.

The drying temperature is generally adjustable for 30-90℃, effectively protecting the color and quality of the material. This machine adopts speed governing deceleration motor, adjustable belt speed and adjustable drying effect.

Parameters

|

Item |

Parameter |

|

Material |

SUS304 stainless steel |

|

Power |

50kw |

|

Capacity |

200kg/h (Fresh material) |

|

Physical Size |

22000*2000*2200mm |

|

Heat mode |

Heat pump |

|

Heat Temperature |

Adjustable(35℃-95℃) |

|

Drying Time |

10 hours/Adjustable |

|

Layer |

5layers |

|

Convey mode |

Automatic |

Our Services

We can try our best to provide you the good services as below:

1.Offer the most professional design or detail plan.

2.Expert engineers install for you overseas.

3.Free to amend and change the parts in two years.

4.Free technical guidance from our professional technical team.

5.Provide kinds of certificates.

6.Provide refrigeration system if necessary.

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment, excellent talents and continuously strengthened technology forces for Renewable Design for Potato French Fry Machine - Air energy intelligent drying line – INCHOI , The product will supply to all over the world, such as: Dominica, Estonia, UK, We insist on the principle of "Credit being primary, Customers being the king and Quality being the best", we are looking forward to the mutual cooperation with all friends at home and abroad and we will create a bright future of business.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.